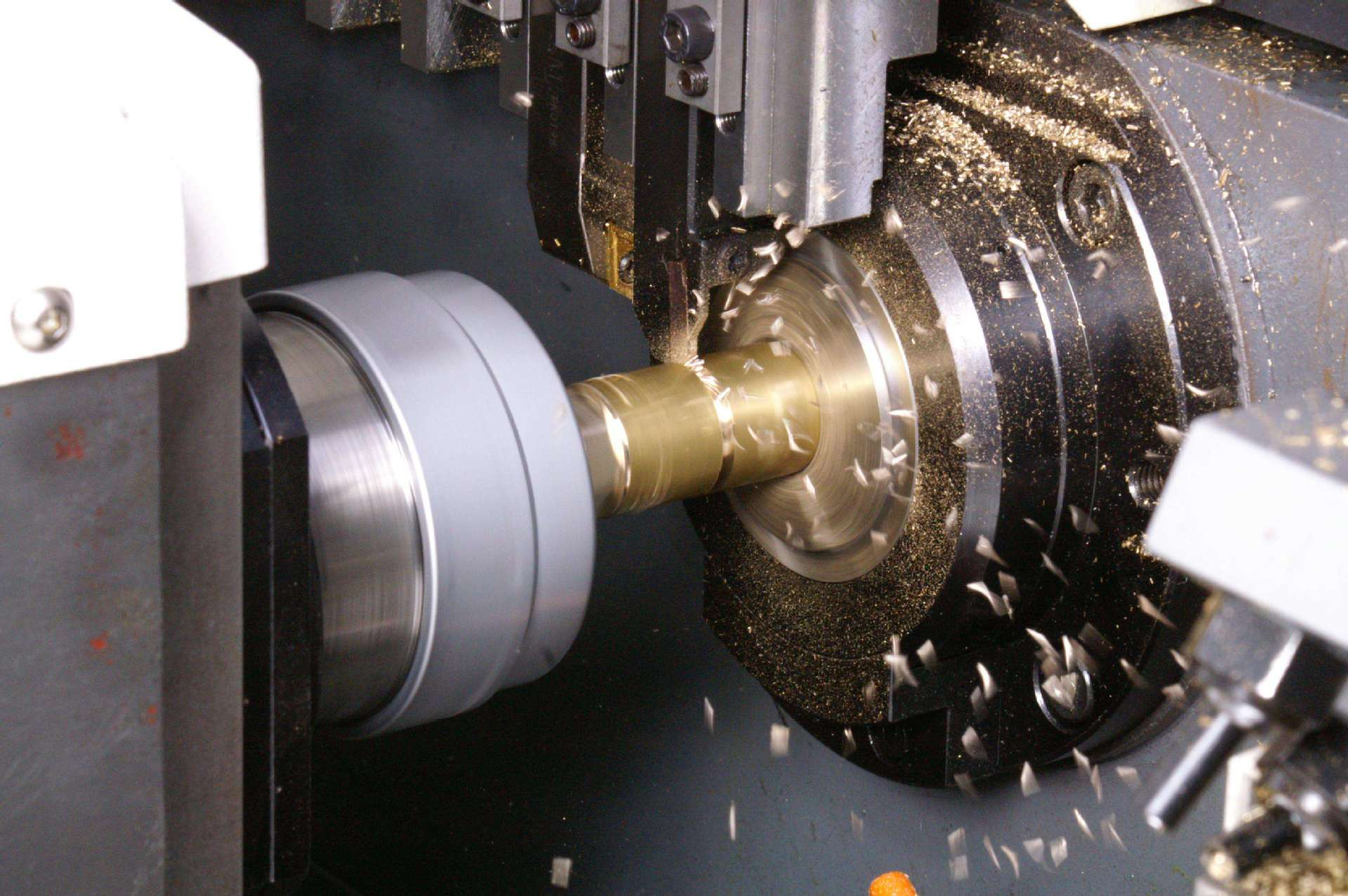

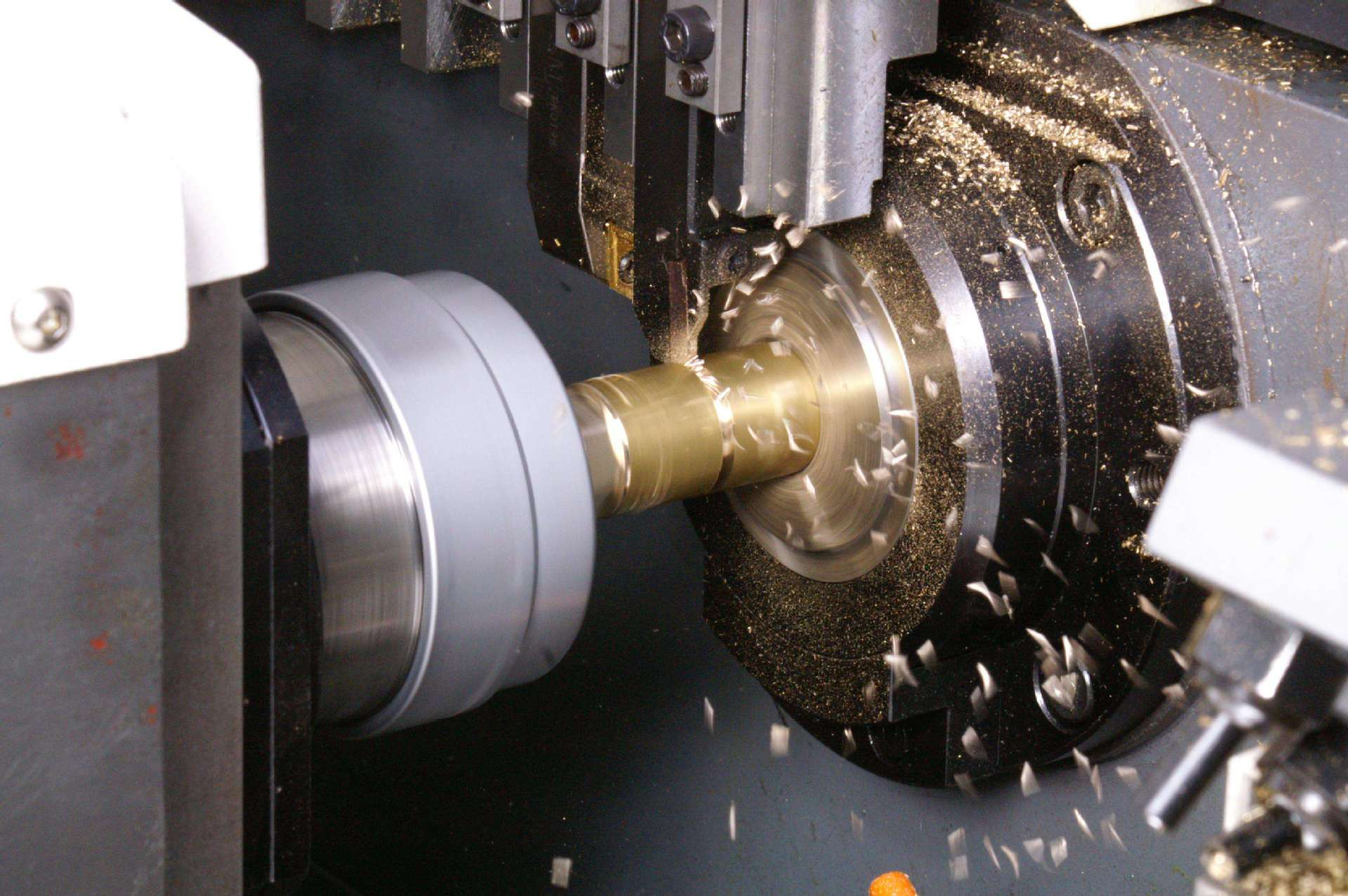

As the core functional component enabling high-speed rotational motion in machine tools, the spindle system's speed, precision, rigidity, and stability directly determine the machine tool's machining capability and surface quality. In high-speed cutting scenarios, spindle speeds have exceeded 20,000 r/min, while the demand for nanoscale surface roughness places even stricter requirements on the spindle's dynamic characteristics. The following systematically analyzes the efficient operation guarantee system of spindle systems from four aspects: structural composition, performance indicators, failure modes, and optimization strategies.

The spindle system consists of mechanical structure and drive control components:

Mechanical Core Components: Include the spindle body (typically made of 40CrNiMoA alloy steel, quenched and tempered to HRC28-32), bearing system (ceramic ball bearings or magnetic bearings for high-speed scenarios), transmission mechanism (synchronous belts, gears, or direct drive), and tool clamping device (with BT40 and HSK-A63 as the main taper types for tool shanks).

Drive and Control System: Spindle motor (asynchronous or permanent magnet synchronous motor, power range 5-60kW), frequency converter (supporting stepless speed regulation from 0-30,000 r/min), dynamic balance control system (real-time monitoring and compensating unbalance), and some high-end systems equipped with thermal error compensation modules.

Speed Characteristics: Maximum speed (3,000-8,000 r/min for ordinary machine tools, 15,000-40,000 r/min for high-speed machining centers), speed stability (fluctuation ≤±1%), and acceleration time (from 0 to maximum speed ≤5 seconds).

Accuracy Indicators: Radial runout (≤0.001mm), axial movement (≤0.0005mm), end face runout (≤0.0015mm). These indicators may slightly amplify at high speeds due to centrifugal force.

Rigidity Parameters: Static stiffness (spindle front-end deflection ≤0.001mm/N), dynamic stiffness (resonant frequency ≥200Hz). Insufficient rigidity will intensify cutting vibration and affect surface quality.

Rotational Accuracy Attenuation: As speed increases, bearing clearance changes due to thermal expansion, potentially increasing radial runout by 30%-50%. For example, a spindle with a runout of 0.0008mm at 10,000 r/min may reach 0.0012mm at 20,000 r/min.

Vibration Response: Near the critical speed (usually 60%-80% of maximum speed), the spindle system may resonate, with amplitude increasing 5-10 times. Dynamic balance and structural optimization are required to avoid resonance zones.

Thermal Stability: During high-speed rotation, frictional heat from bearings and motor heating can cause the spindle temperature to rise by 30-50℃, leading to axial elongation of 0.05-0.1mm and radial expansion of 0.002-0.005mm, directly affecting machining accuracy.

Bearing Configuration: The contact angle of angular contact ball bearings (15°, 25°, 40°) determines rigidity and speed adaptability. Larger angles suit heavy cutting, while smaller angles suit high-speed scenarios. Bearing preload that is too high increases heat generation; too low reduces rigidity, requiring dynamic adjustment (e.g., 20% reduction at high speeds).

Dynamic Balance Status: Residual unbalance exceeding G0.4 grade (allowing ≤0.4g·mm/kg at 20,000 r/min) causes high-frequency vibration, requiring rebalancing after tool changes.

Tool System Impact: Fit accuracy between the tool shank and spindle taper (clearance ≤0.001mm), tool overhang length (rigidity decreases by ~40% for every 100mm increase), and tool dynamic balance all amplify the spindle system's dynamic errors.

Bearing Failure: Accounts for ~60% of spindle faults, characterized by abnormal noise (frequency >1kHz), sudden temperature rise (exceeding ambient by 40℃), or intensified vibration, mainly caused by poor lubrication, installation deviation (axial movement >0.002mm), or overload.

Motor Malfunction: Insulation aging of windings (lifespan halved in high-temperature environments) or rotor balance damage, leading to speed fluctuations, reduced torque, and potential spindle shutdown.

Tool Clamping System Failure: Fatigue of the drawbar spring (service life ~10,000 tool changes) reduces clamping force (<15kN), causing tool shank loosening during machining and endangering equipment safety.

Bearing Optimization: Oil-air lubrication (0.1-0.3ml/h per bearing) replaces grease lubrication, reducing friction by 30%. Hybrid ceramic bearings (steel inner ring + ceramic balls) lower temperature rise by 20-30℃ and extend life by 2-3 times.

Thermal Management System: Spindle sleeves with spiral oil-cooling channels (flow 2-5L/min, inlet-outlet temperature difference ≤5℃), combined with temperature sensors (10Hz sampling) for dynamic control, limiting thermal errors to ≤0.005mm.

Condition Monitoring and Early Warning: Vibration sensors (10-10,000Hz range), temperature sensors, and current sensors collect real-time data. Alarms trigger when deviations exceed 15% from baseline, predicting potential faults 200 hours in advance.

Lubrication Management: Grease-lubricated spindles require special grease (NLGI Grade 2, dropping point >180℃) every 200 operating hours. Oil-air systems need daily checks of mist generators (2-3μm particle size) to ensure adequate bearing lubrication.

Cooling System Maintenance: Clean cooler filters weekly and replace coolant quarterly (preferred spindle oil, ISO VG32), maintaining pump pressure at 0.3-0.5MPa.

Operational Parameter Monitoring: Record spindle speed, load rate (avoid long-term >80% rated power), and temperature curves to establish personalized maintenance cycles (e.g., full overhaul every 10,000 hours for high-speed spindles).

Dynamic Balance Calibration: New spindles undergo 整机 balancing (residual unbalance ≤0.5g・mm). After tool changes, online balancing systems (response <1 second) compensate for unbalance, mandatory before high-speed cutting.

Dynamic Preload Adjustment: Hydraulic preload mechanisms adjust bearing preload by speed—15kN for low-speed heavy cutting, 8kN for high-speed light cutting—balancing rigidity and heat dissipation.

Tool System Optimization: Use short tool shanks (overhang <3×diameter), solid carbide tools (G2.5 balance grade), and regularly grind shank tapers (Ra ≤0.02μm) to ensure >90% 贴合率 with spindle tapers.

Magnetic Suspension Spindles: Contactless support eliminates friction, achieving speeds >60,000 r/min with vibration <0.0005mm, suitable for ultra-precision machining (e.g., optical parts) but costing 3-5 times more than traditional spindles.

Integrated Motor Spindles: Direct connection of motor rotor to spindle reduces transmission links, improving dynamic response by 40% and reducing thermal errors by 30%, now standard in high-speed machining centers.

Intelligent Spindle Systems: AI-driven adaptive control adjusts speed and feed based on cutting loads (e.g., sudden force increases), avoiding overload while recording lifecycle data for reliability analysis.

Heavy Cutting: Select large-diameter spindles (≥150mm) with double-row cylindrical roller + angular contact ball bearings for high rigidity (static stiffness >50N/μm) and high-flow cooling (≥10L/min).

High-Speed Finishing: Prioritize motor spindles (≥15,000 r/min) with ceramic bearings and short-taper tool shanks (HSK/CAPTO) to minimize centrifugal effects.

Precision Grinding: Spindles require constant speed control (fluctuation ≤±0.5%), low vibration (amplitude <0.0002mm), and typically use hydrostatic bearings for nanoscale surface roughness (Ra ≤0.005μm).

Optimizing spindle system performance is a systematic engineering, balancing speed, precision, rigidity, and reliability. Through full-process management of "design optimization-condition monitoring-precision maintenance", the mean time between failures (MTBF) can exceed 10,000 hours, with repair time reduced by 50%. Enterprises should select spindle types based on machining needs (material, precision, batch)—ordinary lathes do not require high-speed motor spindles, while high-speed mold milling demands stable spindle performance at 15,000 r/min. Technological advancements in spindle systems remain a core driver of machine tool machining capability.