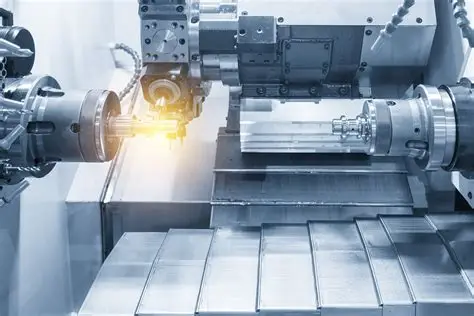

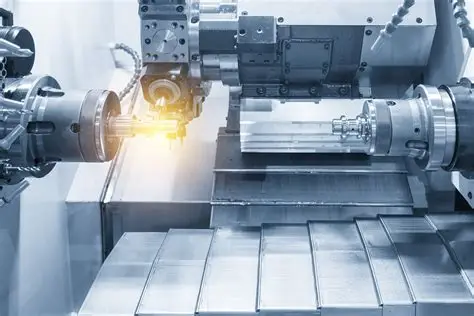

Cutting tools, as the "teeth" directly involved in cutting processes of CNC machine tools, their performance and management level directly determine machining efficiency, surface quality, and manufacturing costs. Data shows that tool costs account for only 3%-5% of total manufacturing costs, but they affect 20% of processing time and 30% of product quality. In the context of intelligent manufacturing, the traditional "experience-based tool selection + manual management" model can no longer meet the production needs of high precision, high efficiency, and multiple varieties. However, tool performance optimization and intelligent management technologies can extend tool life by 30% and reduce inventory costs by 25%. The following constructs a full-process optimization system for CNC machine tool cutting tools from four aspects: tool performance improvement, intelligent management systems, application strategies, and development trends.

Breakthroughs in tool performance first rely on advancements in materials and structures:

Coating is a key means to improve tool wear resistance, and its technological evolution shows multi-dimensional development:

Scientific matching of cutting parameters is the core of exerting tool performance:

Realize transparency of tool circulation through information means:

Efficient allocation of tool resources based on data-driven:

Dynamic scheduling algorithm:

According to the production plan (such as processing 100 pieces of 45 steel flanges tomorrow), the system automatically matches the required tools (such as φ10mm cemented carbide end mill);

Give priority to scheduling regrinded tools (remaining life ≥50%) to reduce new tool consumption;

When tools are insufficient, issue a replenishment warning 8 hours in advance (minimum inventory threshold = 3 days' usage).

Inventory health assessment:

Turnover rate monitoring: the proportion of idle tools (unused for 90 days) is ≤10%, and if it exceeds, it triggers promotion or return;

Safety stock model: automatically adjust the inventory quantity of each tool according to historical consumption data (standard deviation ≤10%);

Capital occupation optimization: control the tool inventory cost within 15% of the total purchase amount.

Grinding and remanufacturing management:

Establish grinding quality standards (such as edge radius ≤0.05mm), and unqualified tools are automatically eliminated;

Statistically analyze the number of times tools can be remanufactured (usually 3-5 times for cemented carbide tools), and if it exceeds, it is recommended to recycle and reuse.

Detect tool abnormalities in advance through data analysis:

Tool selection principles for different material characteristics:

Structural steel (45 steel, 40Cr):

Stainless steel (304, 316):

Select niobium (Nb)-containing cemented carbide (anti-adhesion), combined with internal cooling tools with sufficient cooling;

The cutting speed is controlled at 80-120m/min to avoid work hardening.

High-temperature alloy (Inconel 718):

Use ceramic tools (SiAlON) or CBN tools, vc=30-100m/min;

The tool rake angle is -5°~0° to enhance the edge strength.

Milling processing:

Cavity processing: use a round nose tool (R0.8-R5mm) to reduce the cutting force fluctuation at the corner;

Plane processing: select indexable insert milling cutters (such as 45° face milling cutters) with a feed speed of up to 1000mm/min.

Turning processing:

External circle finish turning: use coated carbide inserts (nose radius 0.4mm) to achieve Ra0.4μm surface;

Thread processing: use cemented carbide thread combs, which is 3 times more efficient than taps.

Hole processing:

Deep hole drilling (length-diameter ratio >5): use gun drills with high-pressure cooling (20-30MPa);

Precision boring: use a fine-tuning boring tool (adjustment accuracy 0.001mm) to ensure IT6 grade tolerance.

The performance optimization and intelligent management of CNC machine tool cutting tools is the in-depth integration of "hard technology" (materials, structures) and "soft systems" (data, algorithms). A new energy vehicle motor housing production line has applied this system, reducing the number of tool changes from 8 times a day to 3 times, and increasing the daily output of a single machine by 15%, which verifies the technical value. In the future, with the advancement of AI algorithms, the Internet of Things, and new material technologies, tools will realize the transformation from "passive adaptation" to "active optimization" and become a key part of intelligent manufacturing. Enterprises should promote the intelligent transformation of tools in stages according to their own product characteristics (such as batch and precision requirements), and prioritize breakthroughs in bottleneck processes (such as precision boring and difficult material processing) to gradually build a full-process intelligent tool management system.