Driven by global "dual carbon" goals and sustainable development concepts, the green transformation of CNC machine tools—core equipment in manufacturing—has shifted from an optional trend to an imperative. In traditional machine tool processing, energy utilization rates are only 30%-50%, and cutting fluid waste treatment costs account for 15% of total operating costs. However, green manufacturing technologies can reduce energy consumption by over 30% and waste emissions by 50%. This transformation not only delivers environmental benefits but also creates significant economic value through resource optimization. The following constructs a full-lifecycle low-carbon development framework for CNC machine tools from four aspects: green manufacturing connotations, key technologies, evaluation systems, and implementation paths.

Green manufacturing of CNC machine tools spans the entire "design-manufacturing-usage-recycling" process, with multi-dimensional characteristics:

Design Phase: Adopts modular architecture (≥80% component commonality), lightweight materials (20% weight reduction vs. traditional structures), and energy-saving layouts (30% reduction in idle energy consumption) to minimize environmental load at the source.

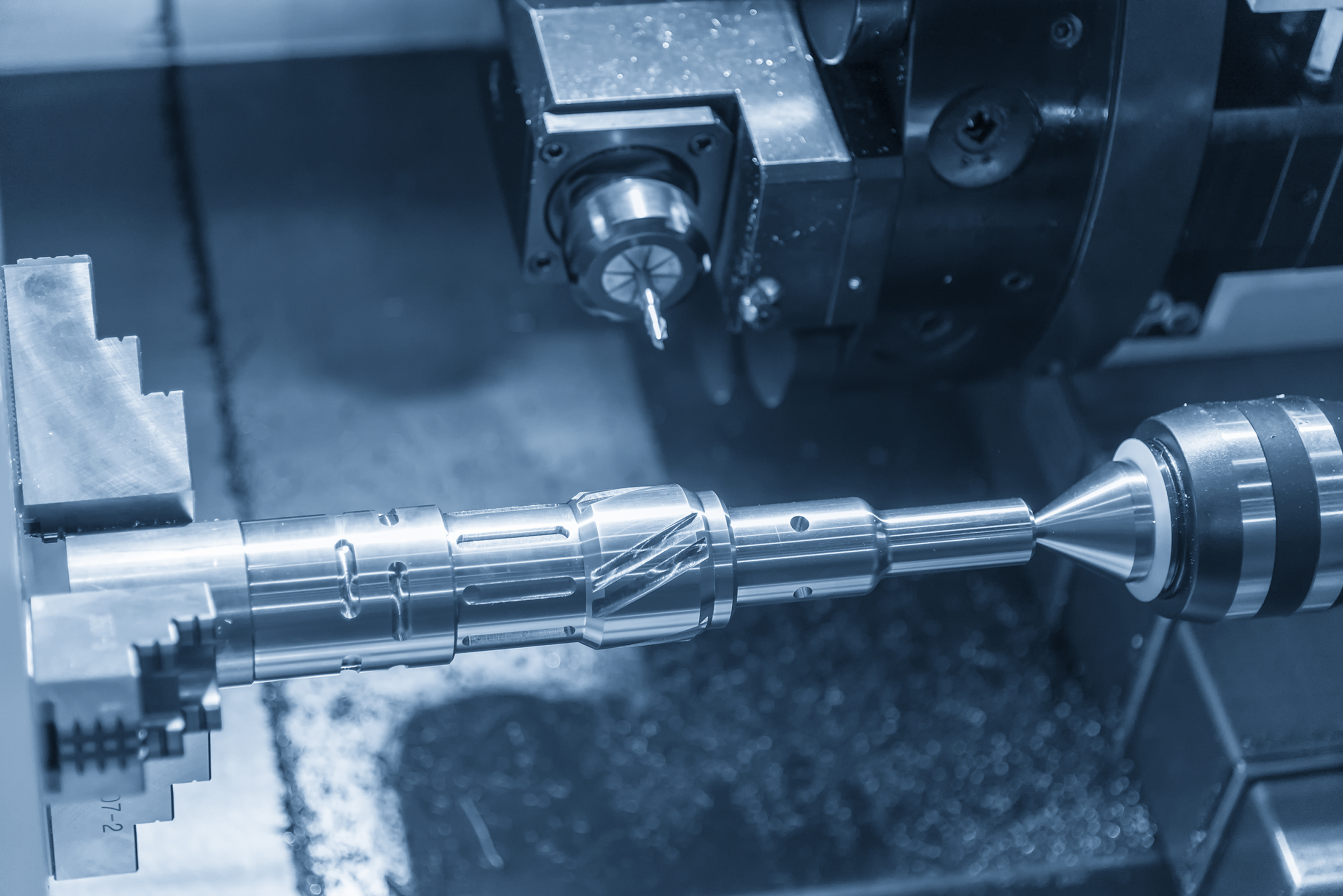

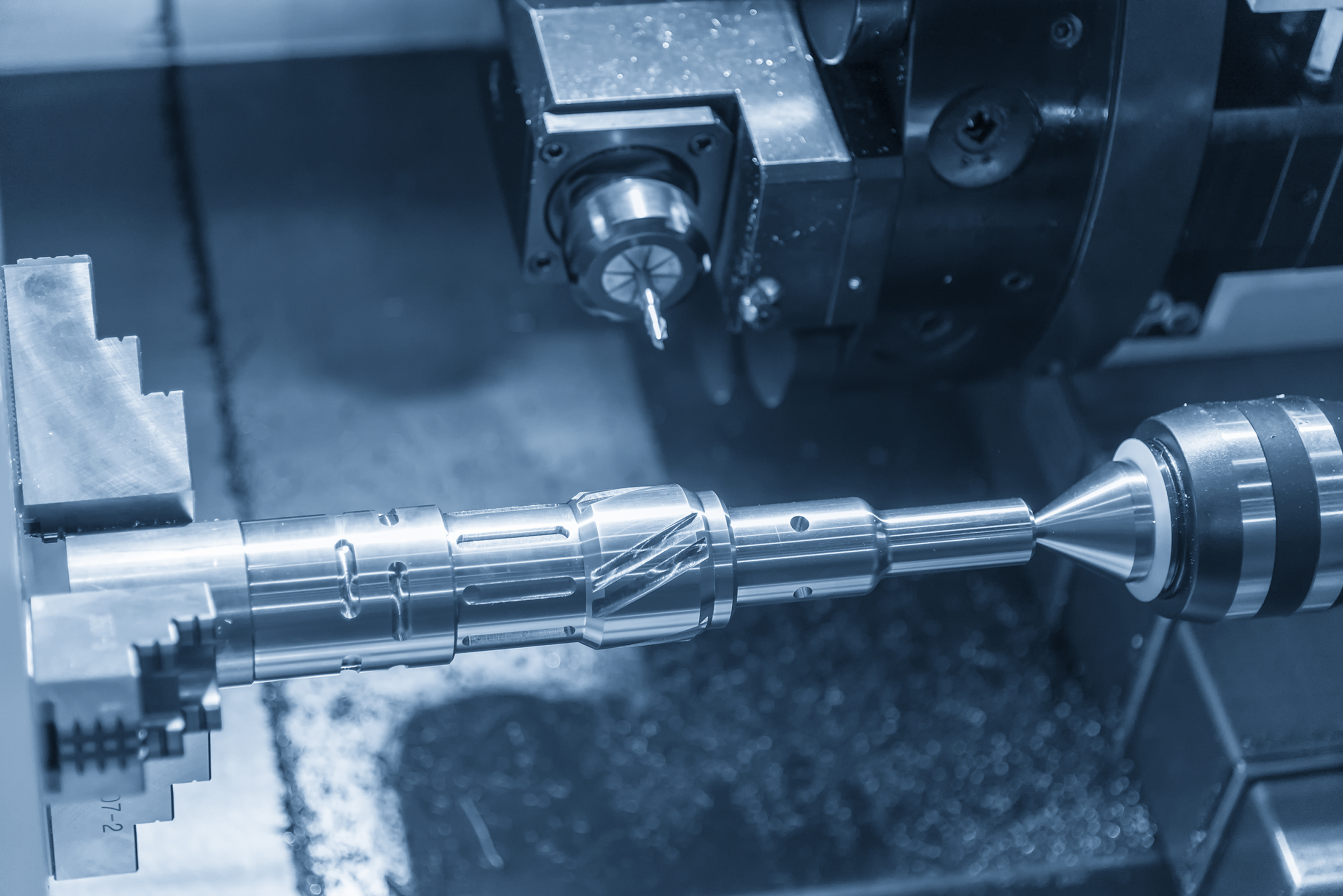

Manufacturing Phase: Reduces resource consumption and pollution through precision casting (30% less excess material) and dry cutting (no cutting fluid consumption).

Usage Phase: Focuses on improving energy efficiency (≤0.5kWh/kg unit processing energy) and resource circulation (≥90% cutting fluid reuse rate), while controlling noise (≤80dB) and exhaust emissions.

Recycling Phase: Achieves ≥90% recycling rate for metal materials (cast iron, steel, etc.), 100% harmless treatment of electronic components, and prevents heavy metal pollution.

Energy Efficiency Indicators:

Machine Tool Comprehensive Energy Consumption (PEC): Ratio of total power consumption (kW·h) to effective processing output (kg) per unit time, with advanced level ≤0.3 kW·h/kg;

Standby Energy Consumption: Power consumption in non-processing state, requiring ≤50W (traditional machines typically 100-200W);

Servo System Efficiency: Permanent magnet synchronous motor efficiency ≥95% at 70% load rate (vs. ~85% for asynchronous motors).

Resource Circulation Indicators:

Cutting Fluid Recycling Rate: Proportion reused after treatment, target ≥95%;

Tool Life Extension Rate: Lifespan improvement through coating and parameter optimization, advanced value ≥50%;

Machine Remanufacturing Rate: Proportion of recyclable components in scrapped machines, requiring ≥70%.

Environmental Impact Indicators:

Noise Emission: ≤80dB(A) at operator position, 5-10dB lower than national standards;

Exhaust Emission: Oil mist collection efficiency ≥99% with emission concentration ≤0.5mg/m³;

Solid Waste Generation: ≤50kg waste chips and residue per ton of processed workpiece (80-100kg with traditional processes).

Intelligent Power Management Systems:

Variable frequency spindles (50-15000r/min range) automatically adjust power output based on load, reducing no-load energy consumption by 60%;

Servo systems integrate energy feedback devices, converting braking energy into electricity for grid 回馈 (≥30% recovery rate), saving up to 1000kWh/year per machine.

Energy-Efficient Thermal Error Compensation:

Optimized cooling oil circuits through temperature field simulation (on-demand flow regulation) reduce spindle cooling system energy consumption by 40%;

Adaptive thermal error compensation algorithms reduce reprocessing energy consumption caused by temperature fluctuations (15%-20% reduction).

Lightweight and Low-Resistance Design:

Machine beds use topology-optimized cast iron-composite structures (e.g., cast iron + glass fiber), reducing weight by 25% and motion energy consumption by 18%;

Guideway friction coefficient reduced to 0.001 (vs. 0.1-0.2 for traditional sliding guides), cutting feed axis drive power by 50%.

Dry Cutting and Minimum Quantity Lubrication (MQL):

CBN tools enable completely dry machining of hardened steel (HRC55-65), reducing annual waste fluid emissions by 1200L per machine;

MQL systems deliver precise oil supply through oil-air mixing nozzles (5-10μm atomized particles), consuming ≤50mL/day—1/100 of traditional flood cooling.

Cutting Fluid Regeneration Technologies:

Three-stage filtration systems (5μm→1μm→0.1μm) with oil-water separators extend cutting fluid service life from 3 months to 12 months;

Electrodialysis treatment removes 99% of metal ions and impurities, restoring ≥90% of fluid performance.

Waste Chip Resource Utilization:

Inline briquetting devices compress aluminum chips into ≥2.3g/cm³ cakes, reducing transportation costs by 60% and smelting recovery rate to 98%;

Cast iron chips converted to recycled cast iron via direct reduction, consuming 40% less energy than primary cast iron production.

Modular and Easy-Disassembly Design:

Key components (spindles, guides) use standardized interfaces, reducing replacement time to 2 hours (vs. 8 hours traditionally) for easier maintenance and upgrades;

≥90% of fasteners use unified specifications (e.g., hexagon socket bolts), improving disassembly efficiency by 50% to facilitate remanufacturing.

Core Remanufacturing Technologies:

Laser cladding repairs spindle bearing wear (0.5-2mm coating thickness) with 0.01mm dimensional accuracy, restoring 90% of new part performance;

CNC system upgrades retain 70% of hardware, replacing only motherboards and displays at 60% lower cost than new systems.

Eco-Friendly Material Substitution:

Cutting fluids use biodegradable formulations (≥90% biodegradation rate) with ≤100mg/L COD after disposal, reducing wastewater treatment difficulty;

Machine enclosures use ≥30% recycled plastic with comparable mechanical properties to virgin materials (impact strength ≥20kJ/m²).

Short-Term (1-2 years):

Retrofit existing equipment with energy-saving modifications (variable frequency devices, energy-efficient motors) with ≤1-year payback periods;

Promote MQL and cutting fluid regeneration technologies to achieve initial reductions in resource consumption.

Medium-Term (3-5 years):

Prioritize green-certified models for new purchases (e.g., meeting ISO 14955 energy standards);

Establish machine remanufacturing lines to achieve ≥50% recycling of waste components.

Long-Term (5-10 years):

Build green manufacturing digital platforms for real-time monitoring and optimization of energy consumption and emissions;

Form a full-industry-chain green ecosystem from design to recycling, reducing unit product carbon emissions by 50%.

Digital Twin-Enabled Green Manufacturing:

Virtual simulation optimizes machining paths, reducing idle energy consumption by 40%;

Energy consumption digital models enable dynamic efficiency optimization (±5% accuracy) during processing.

Low-Carbon Technology Integration Innovation:

Develop photovoltaic-direct-drive CNC machines (≥30% photovoltaic power) with energy storage for off-grid operation;

Research bio-based cutting fluids (e.g., vegetable oil derivatives) achieving 100% biodegradation.

Product-as-a-Service Models:

Machine tool manufacturers shift from equipment sales to "pay-per-processed-unit" models with built-in energy-saving algorithms;

Establish regional shared tool centers to extend tool life by 60% through professional management.

The green manufacturing transformation of CNC machine tools is not a simple technology stack but a systemic restructuring of manufacturing models. Practice at a new energy auto parts enterprise shows that green manufacturing retrofits reduced workshop energy consumption by 32% and waste treatment costs by 45%, with full investment recovery in 2 years. As carbon neutrality goals advance, green performance will become core competitiveness for CNC machines, driving manufacturing's fundamental shift from "scale expansion" to "quality efficiency." Enterprises should early deploy green technologies to convert environmental advantages into market advantages, seizing opportunities in the low-carbon era.