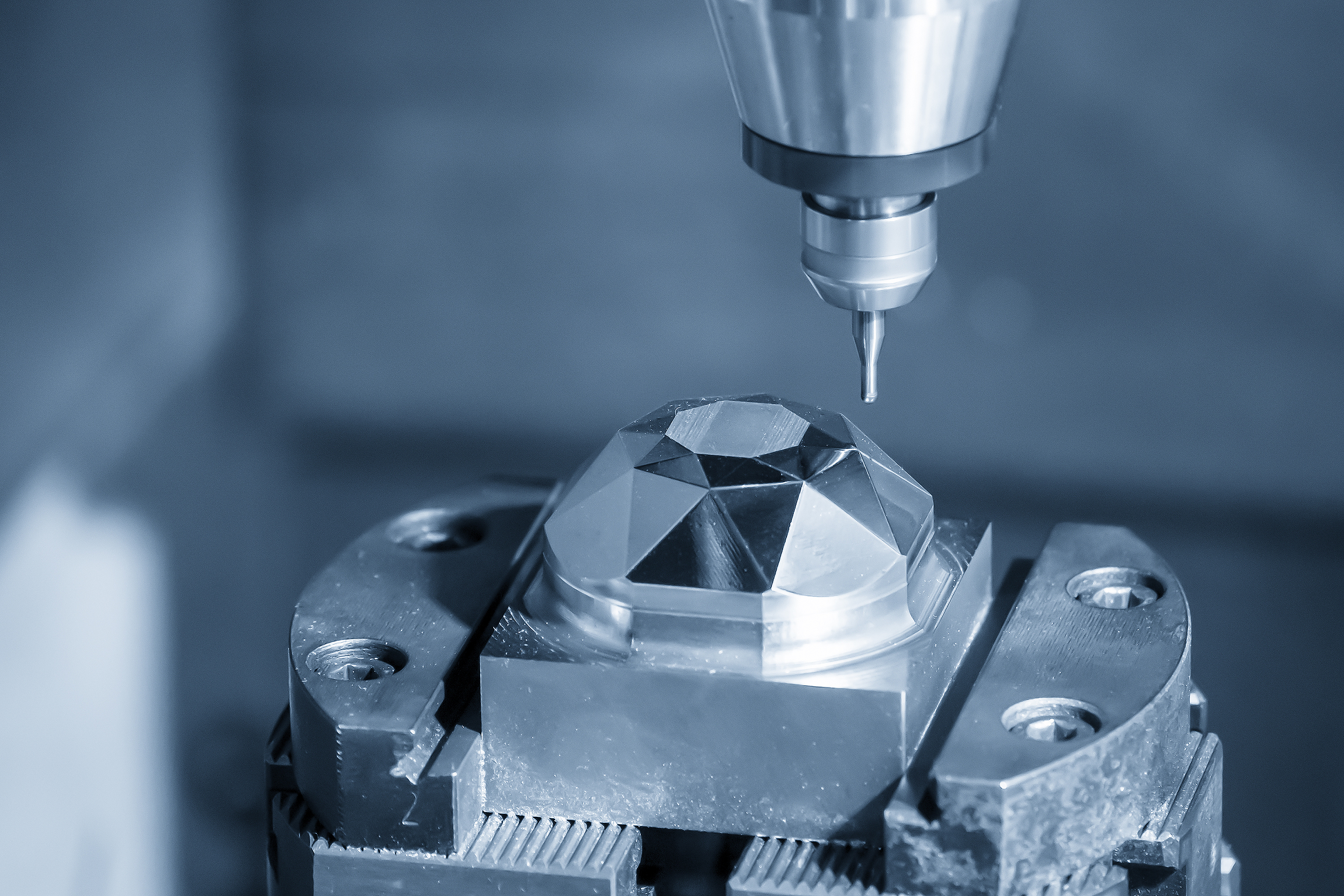

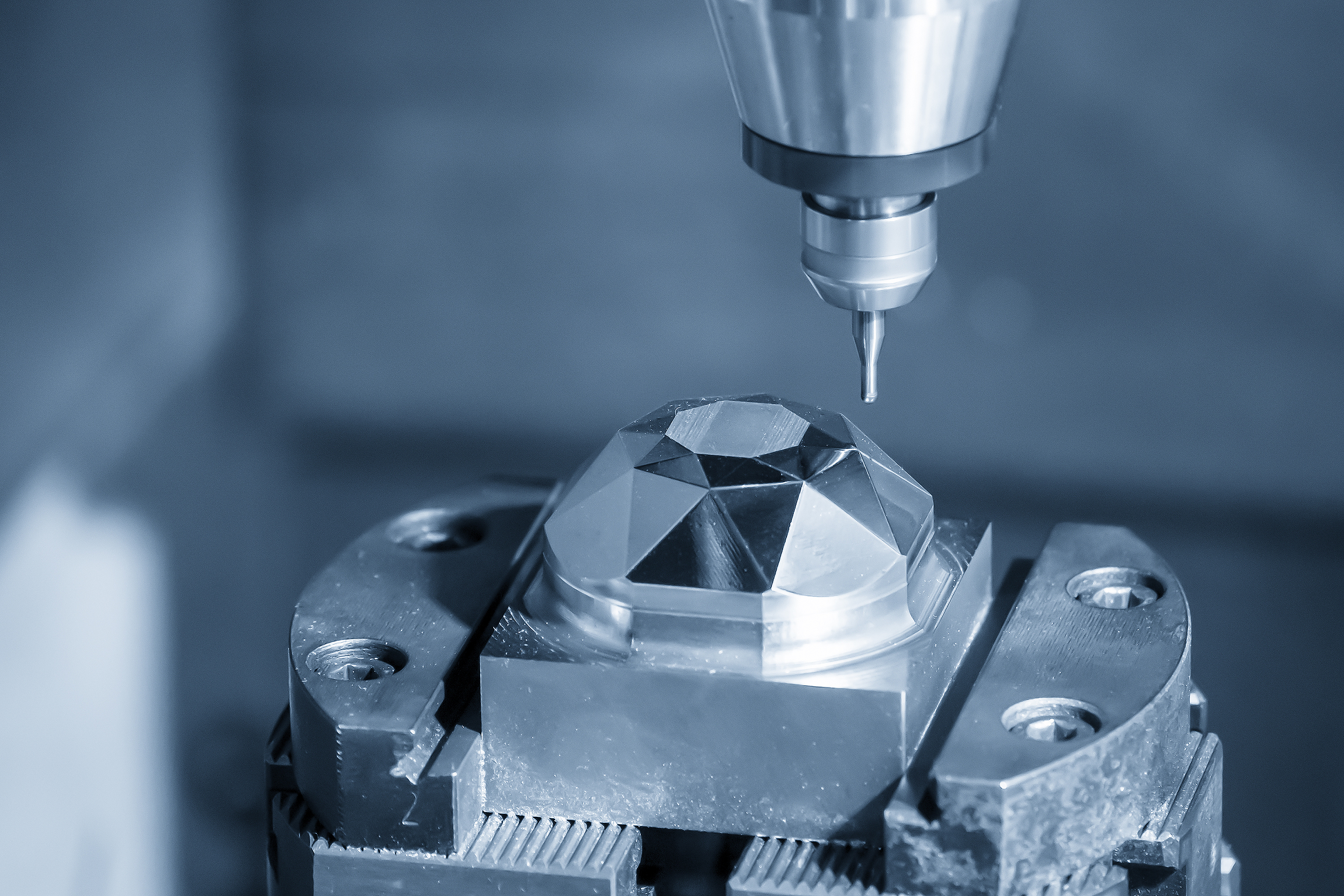

With the growing demand for high-end manufacturing, 5-axis simultaneous machining centers are gradually moving from "niche equipment" to more factory workshops. However, many enterprises often face issues such as "incorrect selection, improper use, and difficult maintenance" due to misunderstandings about 5-axis simultaneous machining centers during procurement and operation. Combining practical application scenarios, this article sorts out the key selection points, common misconceptions, and maintenance methods of 5-axis simultaneous machining centers to help you avoid risks and maximize the equipment's value.

I. Avoid Pitfalls in Selection: Don’t Just Focus on "Axis Count" — These 3 Core Indicators Are Critical

When selecting 5-axis simultaneous machining centers, many enterprises easily fall into the trap of "only focusing on axis count and brand" while ignoring key indicators that match their actual machining needs. This leads to equipment that is "unusable or difficult to use" after purchase. The following 3 indicators must be prioritized:

1. Rotary Axis Structure: Different Structures Adapt to Different Machining Scenarios

The rotary axis structures of 5-axis simultaneous machining centers are mainly divided into two types, with significant differences in their applicable scenarios. Choosing the wrong type will directly affect machining efficiency and precision:

Worktable Rotation Type (e.g., A+C axis worktable): Rotary axes are integrated into the worktable, which drives the workpiece to rotate and swing. The advantage of this structure is its strong load-bearing capacity (able to support workpieces of several hundred kilograms or even tons), making it suitable for machining large, heavy parts (such as wind turbine hubs and large molds). However, its limitation is that the rotating worktable occupies a certain amount of space; when machining ultra-small precision parts, the worktable's inertia may affect precision.

Spindle Swing Type (e.g., A+B axis spindle head): Rotary axes are integrated into the spindle head, which drives the tool to swing and rotate. This structure excels in flexible movement and fast response, making it suitable for machining small, precision parts (such as aircraft engine blades and medical device components) and enabling more precise angle adjustments. However, its load-bearing capacity is weaker, typically only able to process workpieces under several dozen kilograms.

During selection, first clarify the "weight and size" of the parts you need to machine: for heavy, large parts, prioritize the worktable rotation type; for light, precision parts, the spindle swing type is more appropriate.

2. Precision Indicators: Focus on "Positioning Accuracy" and "Repeat Positioning Accuracy" Instead of Single Parameters

Among the precision indicators of 5-axis simultaneous machining centers, the most critical are positioning accuracy (deviation when the axis moves to the target position) and repeat positioning accuracy (deviation when moving to the same position multiple times). These two indicators directly determine the consistency of part machining:

It should be noted that some manufacturers may emphasize the "accuracy of a single axis" (e.g., Z-axis linear accuracy) in isolation. However, 5-axis machining relies on the coordinated movement of multiple axes; high accuracy of a single axis does not guarantee overall precision. You must require the manufacturer to provide a complete "five-axis positioning accuracy and repeat positioning accuracy test report" (usually tested by a third-party organization using a laser interferometer) to avoid being misled by one-sided parameters.

3. CNC System Compatibility: Match Your Programming Software and Process Requirements

The CNC system of a 5-axis simultaneous machining center not only determines operational convenience but also affects compatibility with programming software and auxiliary equipment. Choosing the wrong system will increase post-commissioning and production difficulties:

If your factory regularly uses mainstream CAM software such as UG or Mastercam, prioritize systems with good post-processing compatibility for these software (e.g., FANUC 31i-B, Siemens 840D sl). This reduces errors during program conversion and shortens debugging time;

If multi-process composite machining (e.g., turn-mill composite, drill-mill composite) is involved, confirm whether the system supports the "multi-channel control" function and can manage the movement of the spindle, rotary axes, and auxiliary axes simultaneously;

If you plan to connect to the factory’s MES (Manufacturing Execution System), select a system that supports industrial Ethernet protocols (e.g., Profinet, EtherCAT) to ensure real-time data upload from the equipment and enable intelligent management.

II. Common Misconceptions: These "Taken-for-Granted" Beliefs Are Wasting Equipment Value

After purchasing a 5-axis simultaneous machining center, many enterprises waste its value or accelerate equipment wear due to misunderstandings. The following 3 common misconceptions must be avoided:

1. Misconception 1: "5-Axis Machines Can Process All Parts — No Need for 3-Axis Machines Anymore"

Although 5-axis simultaneous machining centers are powerful, they are not "all-purpose equipment". For simple parts (such as flat plates and ordinary shafts), using a 5-axis machine is not only "overkill" but also increases costs — the operating cost (electricity, tool wear, maintenance fees) of a 5-axis machine is 2-3 times that of a 3-axis machine. The time to machine a simple flat plate may be similar to that of a 3-axis machine, but the cost is significantly higher.

The correct approach: "Divide tasks" based on part complexity. Use 5-axis machines for complex shaped parts and high-precision curved surface parts, and 3-axis or 4-axis machines for simple parts. Achieve "specialized machines for specialized tasks" to reduce overall production costs.

2. Misconception 2: "As Long as the Equipment Has High Precision, Any Worker Can Operate It"

The operation difficulty of 5-axis simultaneous machining centers is much higher than that of 3-axis machines. Workers not only need to master basic programming and operation skills but also understand the "motion logic of multi-axis simultaneous machining" — such as how to avoid inter-axis interference and optimize tool paths. Allowing untrained workers to operate the machine may result in part scrapping at best, or equipment collisions (e.g., spindle colliding with the worktable) due to operational errors at worst, causing hundreds of thousands of yuan in equipment damage.

The correct approach: Before purchasing equipment, prioritize manufacturers that provide "systematic training" (covering programming, operation, and basic troubleshooting). At the same time, arrange technical backbones to participate in equipment commissioning to familiarize themselves with the equipment’s characteristics and avoid the embarrassment of "no one being able to operate it".

3. Misconception 3: "Maintenance Is Too Troublesome — It’s Fine to Repair It Only When It Breaks Down"

5-axis simultaneous machining centers have complex structures (especially the rotary axes and spindle components). After long-term high-load operation, they are prone to precision loss and component wear. If no daily maintenance is performed and repairs are only done when failures occur, it will not only cause production line downtime (ranging from a few days to several weeks) but also allow minor issues to escalate into major failures (e.g., unadjusted increased clearance of rotary axes will accelerate spindle wear).

The correct approach: Establish a "daily maintenance + regular maintenance" system. Based on the maintenance manual provided by the manufacturer, clarify daily, weekly, and monthly maintenance tasks to avoid affecting equipment life due to lack of maintenance.

III. Maintenance Essentials: Do These 4 Tasks Well to Extend Equipment Life and Maintain Precision

The core of 5-axis simultaneous machining center maintenance is to "protect key components and detect hidden risks in a timely manner". The following 4 maintenance tasks must be implemented effectively:

1. Rotary Axis Maintenance: Focus on Wear Prevention and Clearance Control

Rotary axes are core components of 5-axis simultaneous machining centers and are also the most prone to wear. Maintenance should focus on two aspects:

Lubrication: Before starting the machine daily, check if the rotary axis lubrication system is working properly (e.g., lubricating oil level, lubrication pump pressure) to ensure sufficient lubrication of the rotary axis guideways and bearings, avoiding wear caused by dry friction. Some high-precision rotary axes require special lubricating oil (e.g., low-viscosity, high-cleanliness oil); do not replace the oil type arbitrarily.

Clearance Inspection: Use a dial indicator to check the rotary axis clearance (e.g., radial clearance when the A-axis swings, end face clearance when the C-axis rotates) weekly. If the clearance exceeds the manufacturer’s specified value (usually 0.002-0.005mm), adjust it promptly (e.g., replace bearings, adjust lock nuts) to prevent excessive clearance from affecting machining precision.

2. Spindle Maintenance: Control Temperature and Prevent Contamination

The spindle is critical to machining precision and efficiency. Maintenance should pay attention to:

Temperature Control: The spindle generates a lot of heat when running at high speeds for a long time (e.g., speed exceeding 8000rpm). Ensure the spindle cooling system is working properly (e.g., chiller temperature, flow rate) to prevent precision deviation caused by spindle overheating. After starting the machine, let the spindle run at low speed for 5-10 minutes to stabilize the temperature before starting machining, reducing the impact of temperature changes on precision.

Contamination Prevention: The seals at the front of the spindle (e.g., dust covers, oil seals) are prone to wear. Check the integrity of the seals monthly to prevent chips and coolant from entering the spindle interior and damaging the bearings and spindle taper hole. Before clamping the tool each time, clean the spindle taper hole and tool holder to prevent impurities from affecting clamping precision.

3. Guideway and Ball Screw Maintenance: Prevent Chip Contamination and Regular Cleaning

The X, Y, Z-axis guideways and ball screws are key to ensuring linear motion precision. Maintenance focuses on "preventing chip contamination":

After machining each day, use compressed air (equipped with an oil-water separator) to blow off chips on the guideways and ball screws, then wipe them clean with a cloth. Prevent chips from getting stuck in the guideway gaps and causing scratches.

Check the integrity of the guideway guards (e.g., whether the telescopic guards are damaged) weekly. If the guards are damaged, replace them promptly to prevent chips and coolant from entering the guideway interior.

4. CNC System Maintenance: Prevent Interference and Regular Backup

The CNC system is the "brain" of the 5-axis simultaneous machining center. Maintenance should note:

Interference Prevention: Avoid placing high-power electrical equipment (e.g., welding machines, frequency converters) near the CNC system to prevent electromagnetic interference from causing system errors. The system’s power supply should be grounded separately (ground resistance ≤4Ω) to avoid voltage fluctuations affecting system stability.

Conclusion: Maximizing the Value of 5-Axis Simultaneous Machining Centers Lies in "Correct Selection, Proper Use, and Good Maintenance"

5-axis simultaneous machining centers are not "the more expensive, the better", nor can you "buy them and then sit back and relax". During selection, combine part weight, precision requirements, and software compatibility to avoid the misconception of "only focusing on axis count". During use, match professional operators to avoid "overkill" or "non-compliant operation". During maintenance, focus on key components such as rotary axes, spindles, and guideways to detect hidden risks in a timely manner.

Only by doing well in the three links of "selection, use, and maintenance" can 5-axis simultaneous machining centers truly become a "tool" to improve production efficiency and break through machining bottlenecks, rather than an "expensive decoration".